Research Summary

This research work is focused on innovative approaches for clinical use of additive biomanufacturing. In this program, in collaboration with our industry partners, the group aims to advance medical applications of 3D printing. The overall objective is to make advances in radiotherapy, customised and personalised additively biomanufactured titanium implants, and the development of novel therapies for treating cartilage defects.

Subprograms

Additive biomanufacture of phantoms for radiation dosimetry in lung lesions

In order to emulate the negative effects of high-dose radiation treatment this project will develop an AM method and material to mimic the elastic and radiation properties of lung.

This work will enable a unique novel line of test objects for radiotherapy to address urgent needs in modern radiotherapy where image guidance, dynamic deliveries and high precision are paramount.

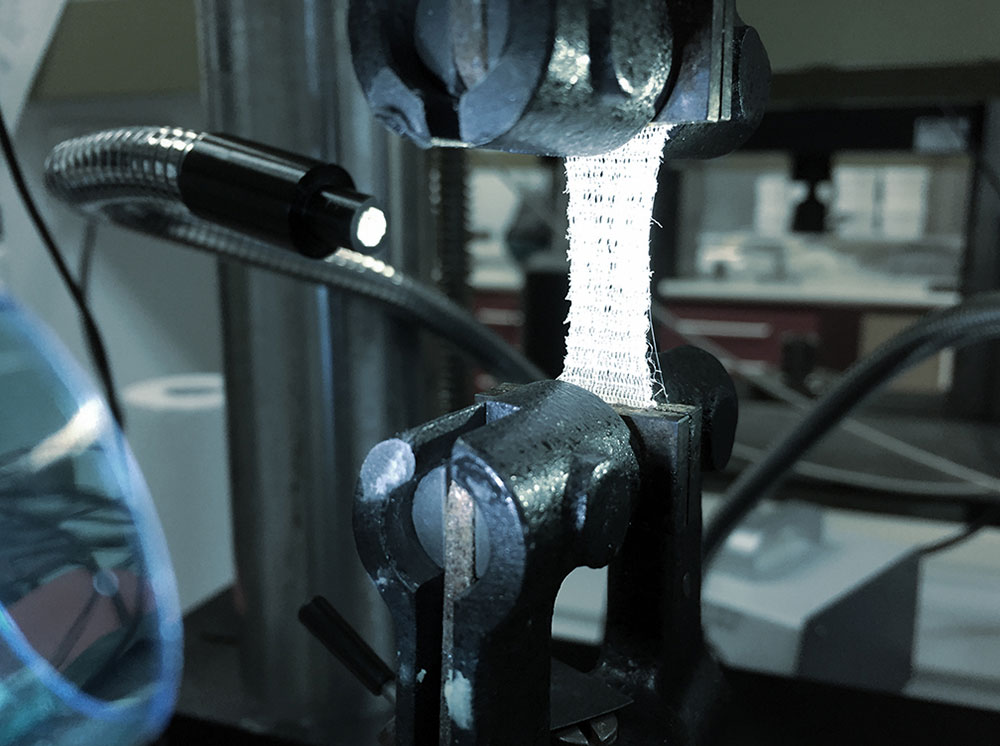

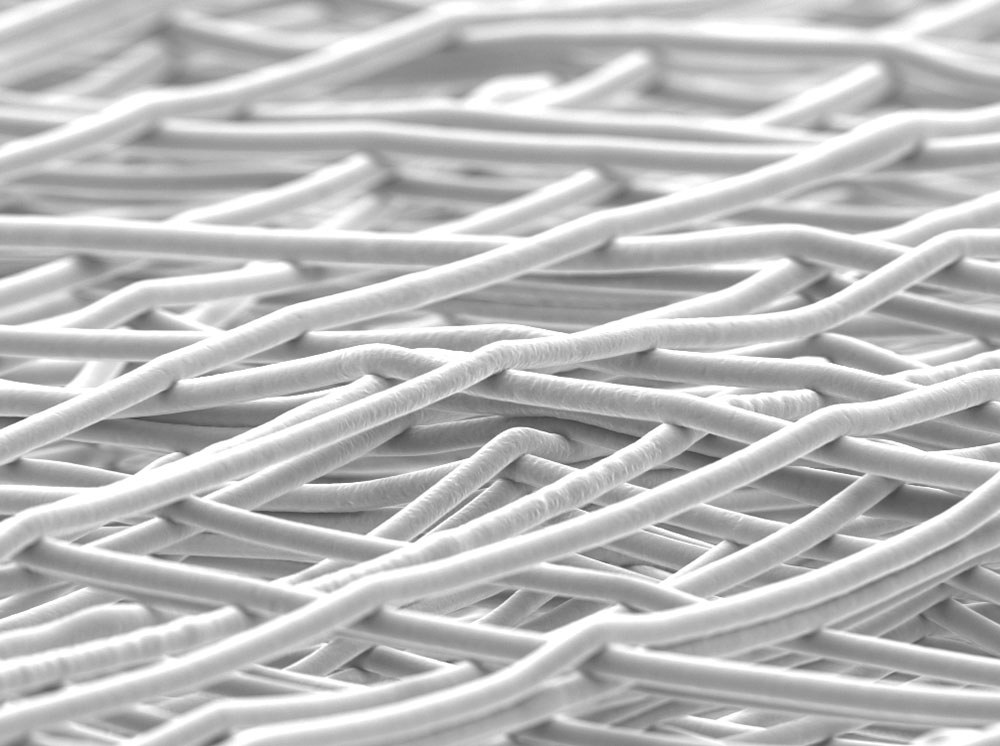

The unloading modulus at target stiffness for additive manufacture of medical implants

In collaboration, the project participants have developed “Just-in-Time” surgical techniques that enable patient-specific AM implant manufacture to occur concurrently with surgery, allowing less invasive surgery with an implant that precisely matches the specific patient requirements. By quantifying the Unloading Modulus of standard AM lattice topologies outcomes will enable a new generation of AM patient-specific implants that truly mimic the mechanical properties of surrounding bone to obviate stress shielding effects and to promote bone in-growth.

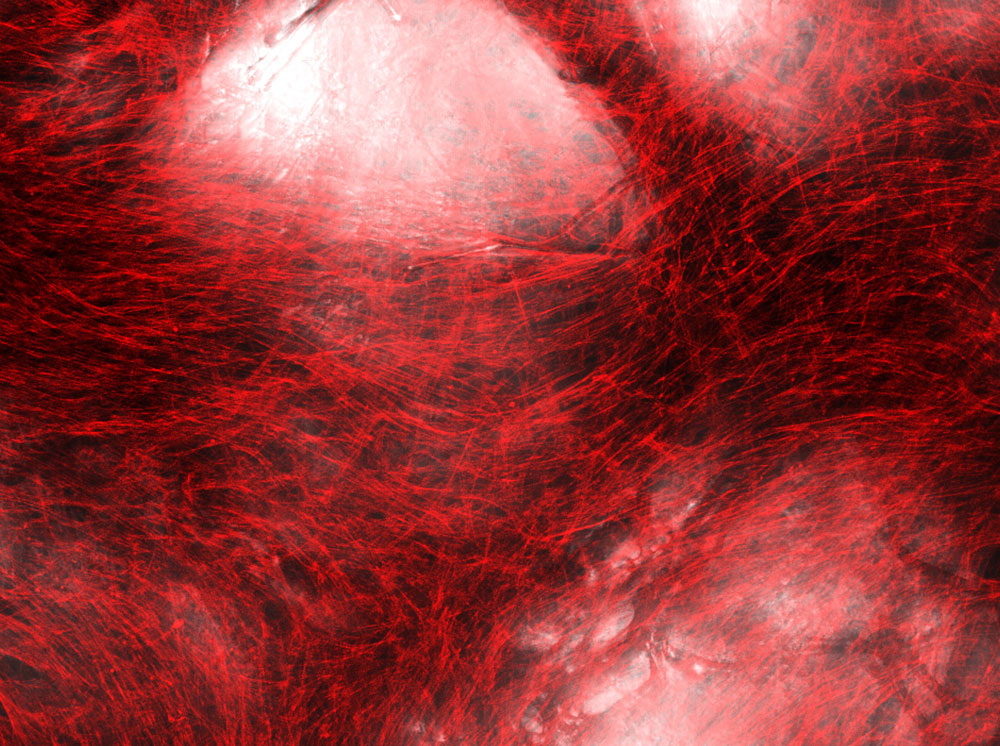

Free-hand 3D printing of biomaterials and stem cells for the treatment of early arthritis

In order to overcome long-term failure of pre-constructed scaffolds the use of “live” additive biomanufacturing technologies during the surgical operation. The “Bio-Pen” is a hand-held 3D printer that can be used by the surgeon to repair or regenerate the damaged cartilage by extruding the bioinks with and without growth factors and/or cells directly into the defect.

Engineering articular cartilage. Is accurate replication of anatomical layered structure important?

Articular cartilage has a complex multi-layered and heterogeneous microstructure. This project aims to identify whether the identical reproduction of this complex structure using 3D printing techniques is necessary to obtain long lasting hyaline cartilage regeneration in vivo. The goal of this project is to use advanced 3D printing techniques to regenerate the multiple layers of hyaline cartilage and compare the in vitro and in vivo performance of these zonal constructs to natural articular cartilage.

Team

Prof Milan Brandt

RMIT University

Prof Gordon Wallace

University of Wollongong

Prof Peter Choong

University of Melbourne

Dr Stephen Beirne

University of Wollongong

A/Prof Martin Leary

RMIT University

A/Prof Travis Klein

Queensland University of Technology

Dr Claudia Di Bella

University of Melbourne